Introduction

In an era driven by rapid innovation, 3D printing technology is reshaping how products are designed, prototyped, and manufactured. From building complex aerospace parts to producing customized medical implants, this technology is unlocking possibilities once considered science fiction. As businesses pursue leaner workflows, sustainability, and personalized offerings, 3D printing is emerging as a key solution at the intersection of creativity and precision.

In 2025, this form of additive manufacturing is no longer limited to experimental labs or large industrial players. It’s crossing into homes, schools, startup hubs, and healthcare facilities, signaling a massive shift in the creation and consumption of products. Whether you’re a business leader, engineer, designer, educator, or a curious enthusiast, understanding the capabilities, trends, and applications of 3D printing is essential to thrive in the modern tech landscape.

What Is 3D Printing and How Does It Work?

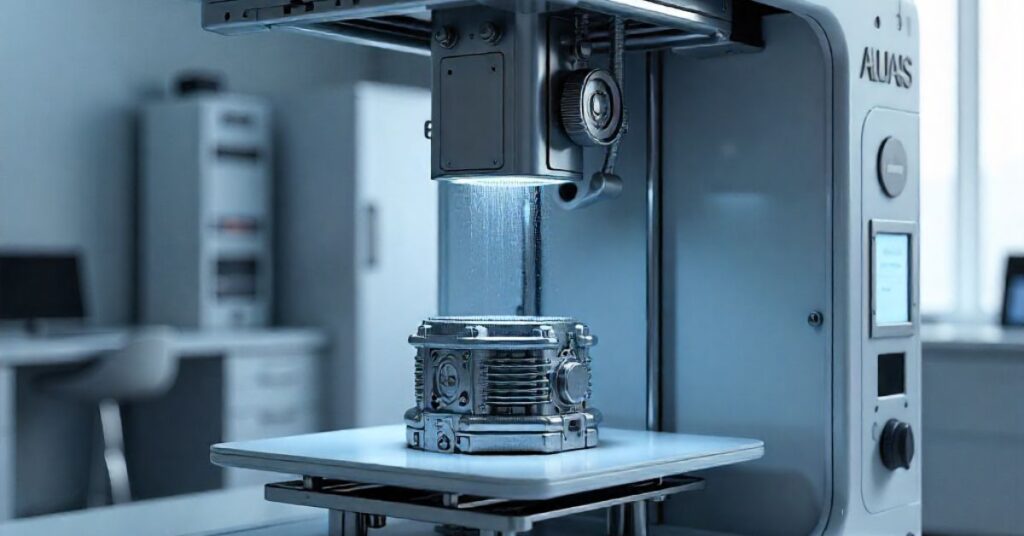

3D printing Technology, also known as additive manufacturing, is a process of creating three-dimensional objects by layering materials based on a digital design. Unlike traditional manufacturing, which often cuts or molds material, 3D printing adds it—making it highly efficient and flexible.

Key Components of the Process:

- Digital Design File: Usually a CAD (Computer-Aided Design) or STL file.

- Printing Material: Plastics, metals, ceramics, resins, and bio-materials.

- 3D Printer: Varies from desktop FDM printers to industrial SLS machines.

- Layer-by-Layer Printing: Material is deposited in thin slices until the object is completed.

This process supports rapid prototyping, customization, and small-batch manufacturing with minimal waste.

The Evolution of 3D Printing: From Concept to Revolution

While 3D printing technology might seem like a modern innovation, it dates back to the mid-1980s when stereolithography was first introduced. However, it wasn’t until the 2010s that the technology gained speed due to open-source development and hardware miniaturization.

Timeline Highlights:

| Year | Milestone |

|---|---|

| 1986 | First 3D printer patent filed by Charles Hull |

| 2005 | DIY 3D printer movement began (RepRap) |

| 2020s | Surge in industrial and medical applications |

| 2025 | Mass adoption across multiple industries |

Today, the focus is shifting toward scalability, multi-material printing, and integration with AI and robotics.

Top Applications of 3D Printing Technology in 2025

The versatility of 3D printing technology is being leveraged in nearly every sector. What sets 2025 apart is the widespread real-world implementation.

Key Industries Benefiting:

- Aerospace: Lightweight components and on-demand part replacement.

- Automotive: Custom tools, parts, and electric vehicle components.

- Healthcare: Implants, prosthetics, and surgical planning models.

- Education: Affordable hands-on learning tools and STEM kits.

- Fashion & Art: Custom wearables, jewelry, and experimental designs.

One standout trend is the rise of on-site production, reducing global supply chain dependencies.

Advantages and Limitations of 3D Printing

While 3D printing brings game-changing benefits, it’s not without trade-offs.

Benefits:

- Customization: Ideal for low-volume, tailored products.

- Sustainability: Limited material waste.

- Speed: From concept to physical part in hours.

- Cost-effective prototyping

Limitations:

- Material Constraints: Not all materials are suitable.

- Structural Integrity: Lower strength compared to forged parts.

- Speed at Scale: Slower than mass production for large volumes.

Understanding these pros and cons is crucial for choosing where and when to employ the technology effectively.

3D Printing in Healthcare: Innovation Meets Precision

Healthcare is arguably the most impactful domain for 3D printing in 2025. From lifesaving implants to bioprinting human tissues, the medical world is embracing custom solutions.

Applications:

- Customized Implants: Tailored to individual anatomies.

- Orthopedic Models: Surgical accuracy improvements.

- Dental Care: Fast production of crowns, bridges, and aligners.

- Bioprinting: Printing tissues for drug testing and research.

According to a 2025 report by the WHO, adoption of 3D printing has reduced orthopedic surgical costs by 28% globally.

The Role of 3D Printing in Sustainable Manufacturing

In 2025, sustainability is not optional—it’s central. 3D printing contributes by enabling clean, sustainable, and localized production models.

| Sustainability Factor | 3D Printing Advantage |

|---|---|

| Material Waste | Near-zero waste through precision layering |

| On-Demand Production | Reduces overproduction and storage needs |

| Localized Manufacturing | Cuts global shipping and emissions |

| Recyclable Materials | Many printers now support eco-friendly filaments |

Researchers are exploring bio-based and renewable composites for greener supply chains.

Industry 4.0 and Additive Manufacturing Integration

Industry 4.0—defined by AI, IoT, and smart systems—is increasingly integrating with additive manufacturing.

Integration Outcomes:

- Remote Monitoring: Real-time printer diagnostics via IoT sensors.

- AI-driven Design: Generative design tools optimize structures before printing.

- Digital Twins: Simulating the entire product lifecycle pre-production.

This collaboration enhances productivity, predictive maintenance, and flexibility across verticals.

Consumer-Grade 3D Printers: More Accessible Than Ever

Once priced out of reach, personal 3D Printing Technology in 2025 are affordable and functional enough for homes, classrooms, and small startups.

Top Trends:

- Pre-assembled Machines: Easy setup and use.

- User-Friendly Software: Beginner-friendly slicers and design platforms.

- Multicolor & Multi-material: Embedded capabilities in hobbyist models.

Popular use cases include DIY gadgets, educational tools, fashion accessories, and replacement parts. The community-driven ecosystems like Thingiverse and Printables continue fueling creativity.

Cost Analysis: Is 3D Printing Economically Viable?

As costs drop and precision increases, the economics of 3D printing are shifting in favor of small- to mid-scale use cases.

| Cost Factor | 3D Printing (2025) |

|---|---|

| Initial Investment | $300–$5,000 (consumer to industrial) |

| Material Cost | $20–$150 per kg (varies by type) |

| Production Speed | Fast for prototypes, slower at scale |

| Customization | Low-cost high-value customization |

Especially for prototyping and custom components, the ROI continues to grow.

Future Trends: What’s Next for 3D Printing?

Future growth of 3D printing technology is anchored in advanced materials, AI integration, and mass innovation.

What’s Coming:

- 4D Printing: Materials that change shape post-print due to environmental stimuli.

- Atomic-Level Manufacturing: Nano-precision for electronics and sensors.

- Print Farms: Fully automated production facilities.

- Cloud Printing Services: Upload a file, print remotely, and deliver anywhere.

According to Deloitte (2025 Innovation Outlook), the additive manufacturing market is projected to exceed $65 billion USD by 2028, driven by enterprise digitization and industrial diversification.

FAQs

Can 3D printers use metal?

Yes, specialized industrial machines can print using metal powders like titanium, steel, and aluminum.

Is 3D printing environmentally friendly?

It reduces material waste significantly but environmental impact depends on material choice.

How long does it take to print something?

It can range from minutes to several hours based on size and complexity.

Are 3D printed items durable?

Durability varies. Plastic prints may be brittle, while metal printed parts can rival forged ones.

What software is needed for 3D printing?

Most use CAD software for design and slicer software to prepare files for the printer.

Conclusion

From personalized medicine to sustainable product design, the evolution of additive manufacturing is changing how we imagine, build, and interact with the physical world. As of 2025, 3D printing isn’t just a novel approach—it’s a competitive edge in product development and smart manufacturing.

Whether you’re looking to streamline your production line, improve R&D, boost customization options, or reduce supply chain risks, learning how to leverage this technology is key.