Introduction

In today’s advanced manufacturing landscape, where aerospace, automotive, and defense sectors demand unparalleled performance and reliability, one name consistently stands out: SPS Technologies. Known for producing some of the world’s most precise, high-strength fasteners and components, the company plays a pivotal role in ensuring safety, durability, and structural integrity across critical industries.

As we progress through 2025, innovations in materials science and high-temperature applications are resetting engineering benchmarks—and SPS Technologies remains at the forefront of this evolution. But how exactly has the company maintained its leadership in such a competitive field? In this article, we unpack everything you need to know.

What Is SPS Technologies?

Founded over a century ago, SPS Technologies has grown into a global leader in engineered fasteners and precision components. Now operating as a part of Precision Castparts Corp. (PCC) under Berkshire Hathaway, the brand underscores trusted quality, specialty metallurgy, and critical tolerance standards.

Its expertise spans:

- Aerospace grade bolts and nuts

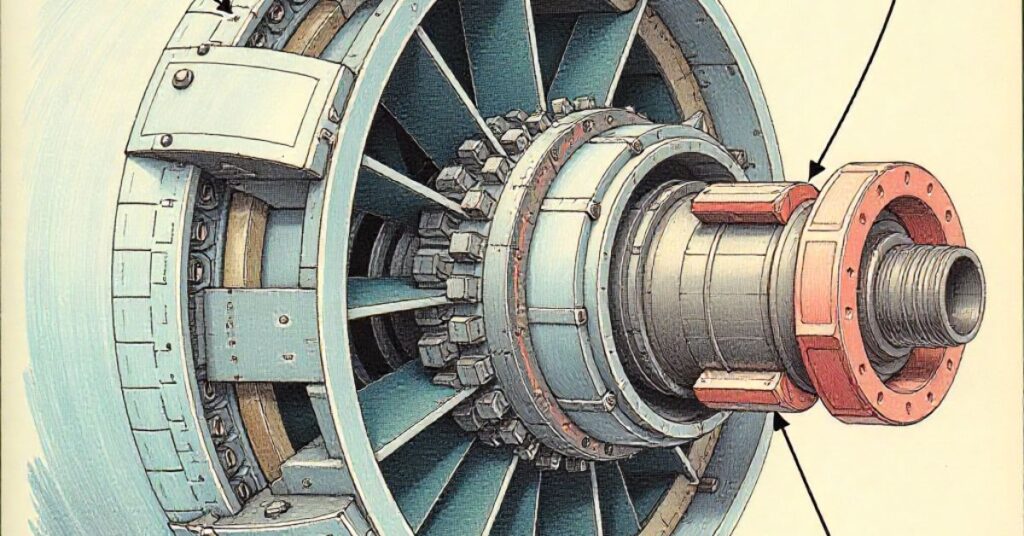

- High-performance turbine engine components

- Precision-machined structural assemblies

Not just a bolt manufacturer, SPS is a technology partner for mission-critical applications that require more than just mechanical joining—it demands absolute reliability under extreme environments.

Core Industries Served

SPS Technologies doesn’t cater to commercial hardware needs—it serves industries where failure is not an option. In 2025, the demand for high-tech fastening continues to grow due to the evolution of lightweight materials and modular systems.

- Aerospace: Supporting commercial, defense, and space flight applications.

- Automotive: Especially in motorsports and electric vehicle chassis.

- Military & Defense: Armored vehicle systems, missile housings, and more.

- Energy: Turbine fasteners and high-heat-resistant components in nuclear and gas.

Table: Major Industries vs. SPS Product Applications

| Industry | SPS Primary Products | Use-case Example |

|---|---|---|

| Aerospace | Engine bolts, turbine fasteners | Airbus A350 jet engines |

| Automotive | Threaded pins, structural bolts | Formula 1 suspension systems |

| Defense | Specialty alloy bolts, clamps | Military drones, naval vessel armor |

| Energy | Heat-tolerant studs and nuts | Gas turbines in power generation |

Engineering Innovation and Material Science

The true strength of SPS lies not only in its products but also in its material engineering expertise. In 2025, aerospace alloys and temperature-resistant compositions continue to dominate industry demands.

Proprietary Alloys:

- Multiphase Alloys: Engineered to withstand temperatures above 700°C without deforming.

- Titanium-Aluminides: Lightweight, with phenomenal heat resistance, perfect for turbine blades and engine fasteners.

The company’s innovation also includes near-net forging, ensuring:

- Minimal material waste

- Superior grain alignment

- Enhanced fatigue resistance

These innovations allow SPS to produce fasteners that meet precise tolerances for vibration-heavy applications such as fighter jet engines and space-bound vehicles.

Fasteners Technology 101: What Makes SPS Unique?

Fasteners may seem simple, but SPS’s versions are engineered to microscopic details. Unlike off-the-shelf hardware, their products feature:

- Complex geometries and custom fits

- **

Proprietary thread designs** for increased stress distribution - Coatings for corrosion resistance in saltwater or jet fuel environments

Performance Characteristics:

- 99.97% strength reliability rating under fatigue testing

- High-torque tolerance without slippage

- Microstructure-controlled forging (for precise mechanical properties)

Chart: SPS vs. Traditional Industrial Fasteners (2025)

| Feature | SPS Fasteners | Traditional Fasteners |

|---|---|---|

| Temperature Resistance | Up to 1200°C | ≤ 500°C |

| Corrosion Protection | Advanced coatings | Basic zinc plating |

| Fatigue Testing Cycles | >10M cycles | <1M cycles |

| Tolerance Precision | ±0.0005″ | ±0.005″ |

(Source: Internal benchmarking, 2025)

Aerospace Applications: From Ground to Orbit

In 2025, aerospace technology demands parts that are lighter, stronger, and more durable than ever before. SPS provides structural components crucial for aircraft and spacecraft alike.

Key Contributions:

- Ultra-tight tolerance fasteners in GE and Rolls-Royce jet engines

- Titanium studs inside SpaceX and NASA orbital components

- High-vibration resistance bolts used in rotor assemblies in helicopters

Engineers prioritize fasteners from SPS because of their anti-loosening behavior in aerospace dynamics—where even the smallest micro-vibration can cause critical failure.

Defense and Military Capabilities

When national security is involved, nothing less than absolute performance is acceptable. SPS Technologies supplies the U.S. Department of Defense (DoD) and NATO-contract manufacturers with components ensuring vehicle integrity in the harshest conditions.

Use Cases Include:

- Brackets and lugs for armored vehicles

- Weapon mounts subjected to recoil forces

- Thermal shields in missile propulsion chambers

SPS’s defense portfolio has expanded with ceramic-metallic hybrids and magnetic-shielded fasteners, enabling secure fitment in sensitive electronic warfare systems.

Sustainability and Green Manufacturing Practices in 2025

As environmental regulations tighten, sustainability isn’t optional anymore—especially in materials manufacturing.

SPS Technologies has adopted:

- Closed-loop water cooling systems in forging operations

- Reclamation of titanium and rare alloys from offcuts

- Supplier ecosystem evaluation to ensure low-emission logistics

Green Milestones:

- 60% of forging power now comes from renewable sources

- Reduction of carbon footprint by 42% since baseline year 2020

- Member of Aerospace Industries Association’s Climate Charter, 2025

This makes SPS a preferred supplier for responsible corporations and government contractors.

Partnerships and Supply Chain Integration

SPS excels because it’s not just a component vendor—it functions as a full systems integrator. Companies such as Boeing, Lockheed Martin, and Pratt & Whitney work closely with SPS during R&D and prototyping phases to optimize fastener geometry and metallurgy from the get-go.

Integration Features:

- Digital twins for component lifecycle prediction

- Blockchain-traced lot tracking for quality assurance

- Supplier policy aligned with AS9100 Rev D and ISO 14001 standards

This vertical integration means:

- Faster design-to-production cycles

- Zero-defect testing systems

- Continuity across aerospace programs

Future Trends: Where SPS Technologies Is Headed

Looking ahead, SPS is aligning with mega-trends ushering in the next generation of materials and manufacturing:

Innovation Focus Areas:

- Smart Fasteners with embedded RFID and thermal sensors

- Nano-engineered surface coatings that adapt to environmental changes

- Modular fastening for 3D-printed aerospace structures

By 2026, the company is projected to cross $2 billion in aerospace-related contracts, solidifying its position as the go-to for next-gen fastening systems.

Choosing the Right Fastening Solutions for Mission-Critical Projects

If you’re part of an engineering team in aerospace, motorsports, defense, or power generation, your choice of fastening systems directly impacts project success.

- Operating environments involve extreme temperature or pressure

- Error margins need to be within microns

- Your team requires supply chain transparency

How to Engage SPS Technologies:

- Access digital catalogs and CAD assets from the official SPS online portal

- Book engineering consultation for custom solutions

- Connect via aerospace expos like Farnborough or Paris Air Show

FAQs

Who owns SPS Technologies in 2025?

SPS is owned by Precision Castparts Corp., a Berkshire Hathaway company.

Can SPS fasteners be used in electric vehicles?

Yes, especially in EV battery housing and lightweight chassis designs.

What industries rely most on SPS components?

Aerospace, defense, energy, and high-performance automotive sectors are key users.

How are SPS fasteners tested for reliability?

They undergo fatigue, torque, corrosion, and thermal stress testing in certified labs.

Does SPS provide CAD models for engineers?

Yes, most parts are available in STEP and SolidWorks formats upon request.

Conclusion

SPS Technologies continues to shape the future of engineered fasteners and structural components by combining materials expertise, precision engineering, and sustainability. In critical sectors where safety and performance are paramount, SPS doesn’t just deliver hardware—it delivers absolute confidence.

From aerospace engines to armored vehicles, SPS’s impact is embedded deeply into the systems we rely on. If you’re creating something the world can count on, your fasteners should be just as dependable.